The Innovation Behind Core Yarn Manufacturing

Core yarn is a game-changer in the textile industry, redefining both manufacturing processes and product applications. As a versatile fabric yarn, core yarn is renowned for its strength, durability, and flexibility, making it an essential material for crafting high-quality textiles. From high-performance activewear to luxurious fashion garments, this innovative yarn is at the forefront of fabric development.

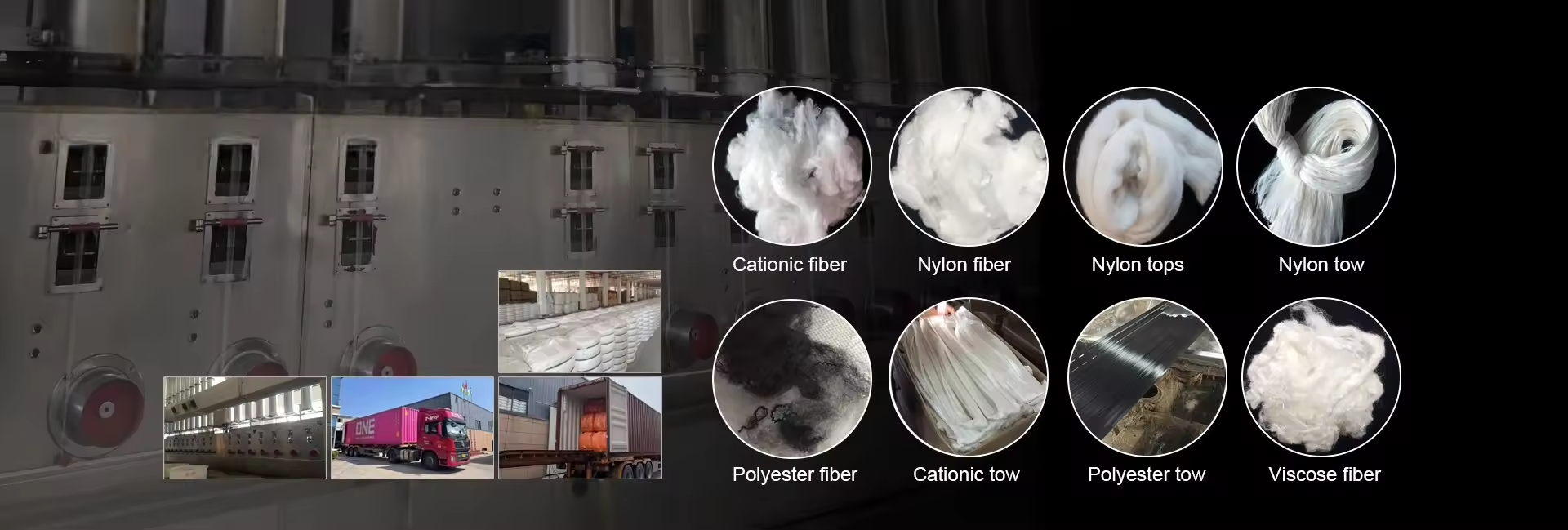

The manufacturing process of core yarn involves advanced technologies and precision engineering. The heart of the production lies in state-of-the-art spinning systems designed to ensure uniformity and efficiency. These systems, equipped with automated draw frames and fiber merging equipment, produce threads and slivers that are unparalleled in quality. Core yarn's adaptability to various applications stems from its unique construction, which often involves a core material wrapped in another fiber. This blend results in enhanced strength and elasticity, creating textiles that are both functional and aesthetically appealing.

Core Yarn Applications: Balancing Strength and Style

The versatility of core yarn has paved the way for its widespread application across industries. For high-fashion enthusiasts, fabrics made from core yarn lend themselves to body-hugging designs like fitted tops and leggings, providing superior comfort and flexibility without compromising style. High elastic core spun yarn, in particular, is a sought-after choice for contemporary fashion due to its excellent stretch and recovery properties. This ensures that garments maintain their shape over time, making them ideal for designer wear and everyday apparel alike.

In industrial uses, core yarn’s durability meets the demands of heavy-duty applications. Whether it's for upholstery, performance gear, or accessories, its robust construction guarantees long-lasting utility. Additionally, core spun yarns with mixed tones and color palettes have introduced a new wave of creative possibilities, enabling designers to experiment with textures and hues for unique statement pieces. Gradient brushed yarns and velvets are perfect examples, offering dynamic textures that elevate the final product.

Sustainability and Future Trends in Core Yarn

As sustainability becomes a growing concern in manufacturing, core yarn production is adapting to meet green standards. The state-of-the-art fiber processing systems used in modern facilities are designed to minimize waste and maximize efficiency. For example, the precise alignment in fiber storage and distribution ensures smooth material flow, reducing unnecessary resource usage. Moreover, core yarn is compatible with an array of eco-friendly fibers, including natural and recycled yarn materials, promoting conscious consumption in the textile industry.

The future of fabric yarn is bright, with continuous innovations refining its structure and utility. New blends and textured designs, such as those found in mohair, velvet, and high-twist linen-like yarns, are pushing the boundaries of craftsmanship. These advancements are not limited to high-end fashion; they also extend to practical applications like breathable summer wear or cozy winter layers.

Core yarn stands as a testament to how technology and creativity can converge to revolutionize textiles. Whether it’s for crafting heirloom-quality garments, high-performance fabrics, or artistic designs, core yarn is truly paving the way for modern textile manufacturing. Designers and manufacturers alike will find that the endless possibilities of core yarn inspire innovations that are just as durable as they are beautiful.