Polyamide PA6 PA66 Nylon, PET polyester, cationic modified polyester, and viscose are popular materials utilized in various industries, particularly for flock micro fiber applications. These fibers have specific properties that make them ideal for countless uses, ranging from textiles to advanced manufacturing. Known for their durability, versatility, and efficiency, these materials are shaping the future of fiber innovation and application.

Nylon, specifically Polyamide PA6 and PA66, has gained prominence because of its superior strength and abrasion resistance, while PET Polyester is celebrated for its chemical resistance and dimensional stability. Cationic modified polyester introduces a unique capability for dyeing darker shades at lower temperatures, and viscose is prized as a sustainable fiber option with a soft, silky texture. Together, these materials are revolutionizing the production and functionality of flock micro fibers.

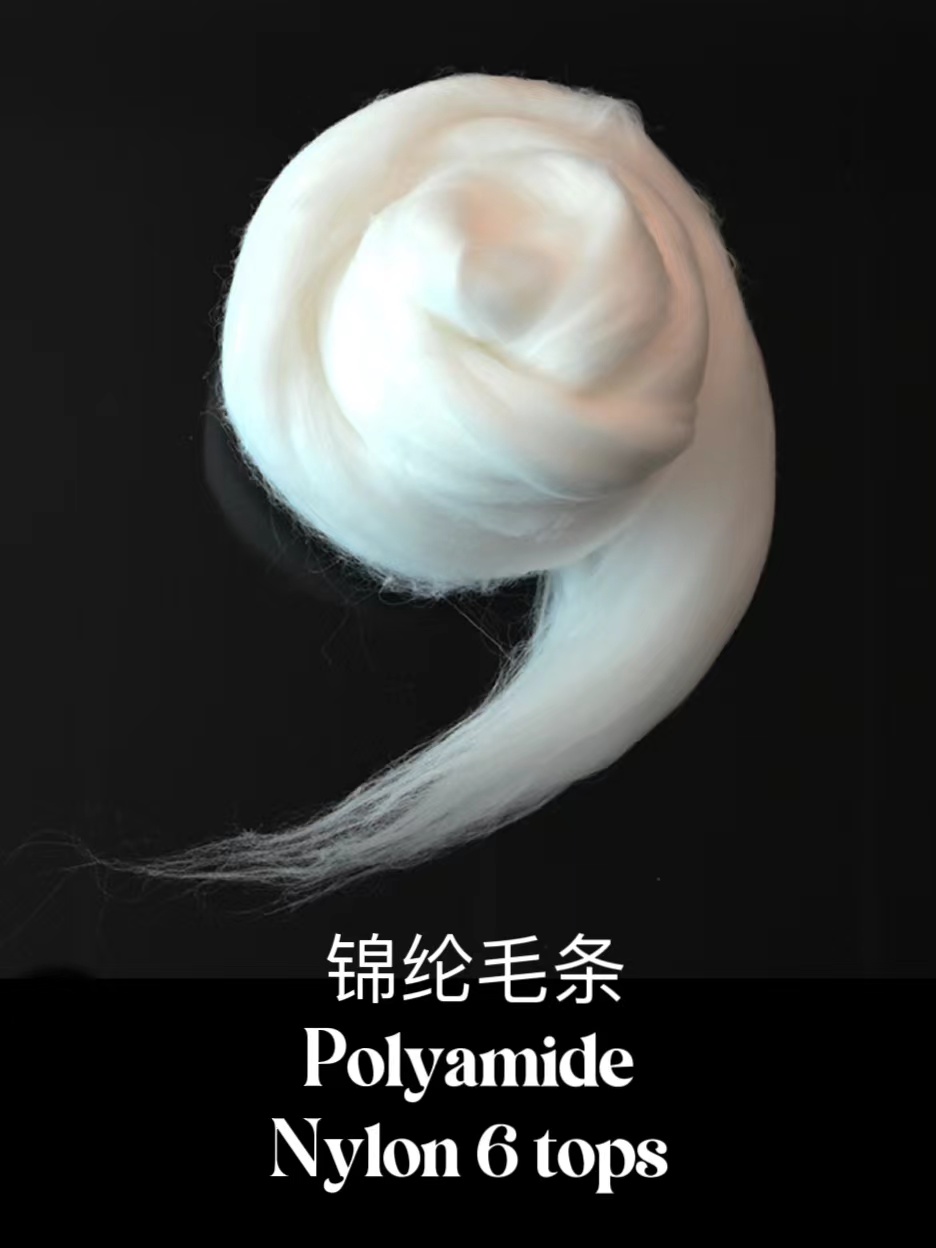

Polyamide PA6 PA66 Nylon: High-Performance and Versatility

Polyamide PA6 PA66 Nylon is one of the most widely used synthetic fibers worldwide. PA6 and PA66 have slightly different properties, but both are valued for their exceptional tensile strength, elasticity, and thermal stability. Flock micro fiber applications, particularly in automotive and industrial textiles, benefit immensely from the use of Nylon PA6 PA66.

Known for its abrasion resistance and resilience, Polyamide PA6 PA66 Nylon is a preferred material for applications requiring toughness. Flock micro fibers made of Nylon enable smooth and durable surfaces, enhancing product longevity. Polyamide also shines in its adaptability; it can be used in various forms, including molded parts, carpet flocking, and synthetic textiles.

Additionally, Nylon provides advantages such as low moisture absorption, making it less prone to damage in humid environments. Its ability to maintain properties in extreme temperatures and resist chemical degradation makes it indispensable in applications where reliability and strength are paramount.

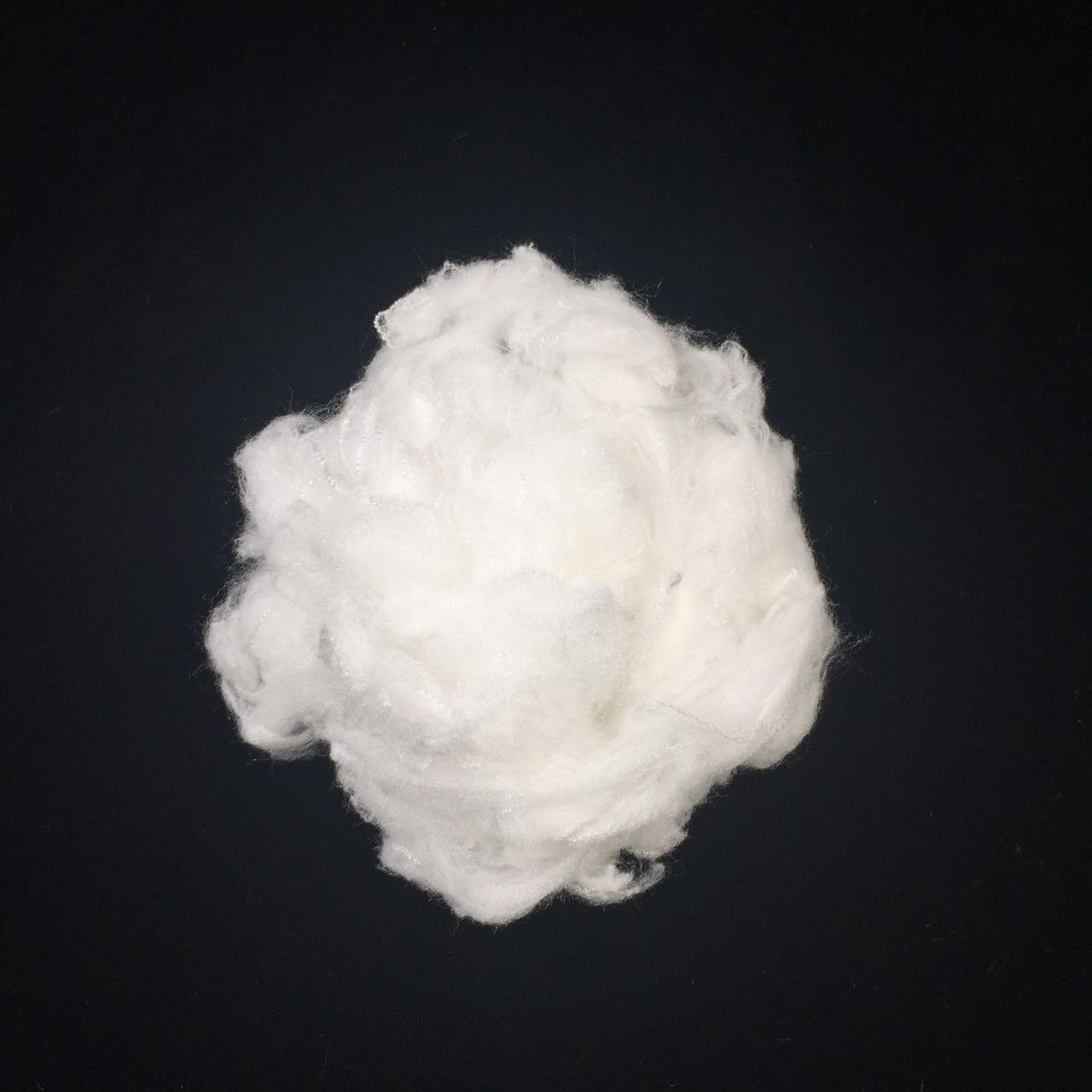

PET Polyester’s Durability and Chemical Stability

PET (Polyethylene Terephthalate) Polyester is a synthetic fiber that offers notable performance in flock micro fiber applications. PET Polyester is recognized for being lightweight, resistant to growth of mold and mildew, and chemically stable, which increases its utility across diverse environments.

One significant characteristic of PET Polyester is its dimensional stability, which allows it to retain its shape even after prolonged use. This property ensures that flock micro fibers remain consistent in their texture and visual appeal, whether used in high-end upholstery or industrial purposes. The strength and durability of PET polyester make it ideal for applications requiring long-lasting wear.

The environmental impact of PET Polyester has also undergone scrutiny, leading to significant advancements in recycled PET polyesters. As sustainability becomes increasingly important, manufacturers are incorporating recycled PET materials into the production of flock micro fibers to meet both functional and ecological standards.

Cationic Modified Polyester: Enhanced Dyeing Capabilities

Cationic modified polyester is a technological innovation within the polyester family, boasting enhanced dyeing capabilities. Traditional polyester fibers typically require high temperatures or chemical carriers to absorb dyes effectively. However, with cationic modification, these fibers can be dyed directly using environmentally-friendly dye processes.

For flock micro fibers, the unique dyeing properties of cationic modified polyester are a game-changer. By facilitating deeper, richer colors without sacrificing the integrity of the fiber, manufacturers are able to create visually appealing and high-quality fabrics. The ability to achieve darker shades with lower energy consumption aligns with the growing demand for sustainable production practices.

Furthermore, cationic modified polyester maintains its mechanical strength and resilience, ensuring that flock micro fibers perform consistently. Its adaptability and dyeing efficiency make it an excellent choice for a wide range of decorative and functional applications.

Viscose: Sustainable and Versatile Fiber

Viscose, derived from regenerated cellulose, is a semi-synthetic fiber offering a balance between performance and sustainability. Its silk-like texture and softness make it a preferred material in the textile industry, and its utility extends to flock micro fibers for both aesthetic and functional purposes.

One of the main advantages of viscose is that it originates from renewable resources such as wood pulp, making it an environmentally friendly option. While durability may be slightly lower than synthetic fibers like Nylon or PET polyester, viscose compensates by offering breathability, comfort, and versatility.

For flock micro fiber applications, viscose can be blended with other fibers such as PET or Nylon to enhance its overall performance while retaining its signature softness. This hybrid approach creates a balanced product suited for premium applications in home décor, fashion, and automotive interiors.

Applications and Benefits of Flock Micro Fiber

Flock micro fibers are fine, lightweight fibers used to create densely packed surfaces with a soft, velvety texture. These fibers are widely used in industries including automotive, apparel, upholstery, and packaging, among others.

The combination of Polyamide PA6 PA66 Nylon, PET polyester, cationic modified polyester, and viscose enables manufacturers to tailor flock micro fibers to specific requirements. Whether the goal is to achieve high durability, vibrant color, or sustainability, these materials provide flexibility and performance.

Furthermore, flock micro fibers are known for their ability to enhance tactile experiences. Products like clothing, furniture, wallpapers, or even packaging material benefit from the smooth texture offered by flock micro fibers. Their lightweight nature also improves production efficiency while maintaining visual and structural appeal.