When exploring the world of high-performance synthetic materials, one name consistently rises to the top: nylon 66 fiber. This incredibly versatile and durable polymer has become a cornerstone in countless industries, offering a unique combination of strength, resilience, and adaptability. Also known by its chemical shorthand, PA66 fiber, this material is engineered to meet the most demanding specifications, making it a go-to choice for everything from advanced textiles to critical automotive components. Leaders in material science, such as INVISTA, have perfected the creation of this polymer, ensuring that every fiber delivers on the promise of quality and performance.

Understanding Nylon 66 Production

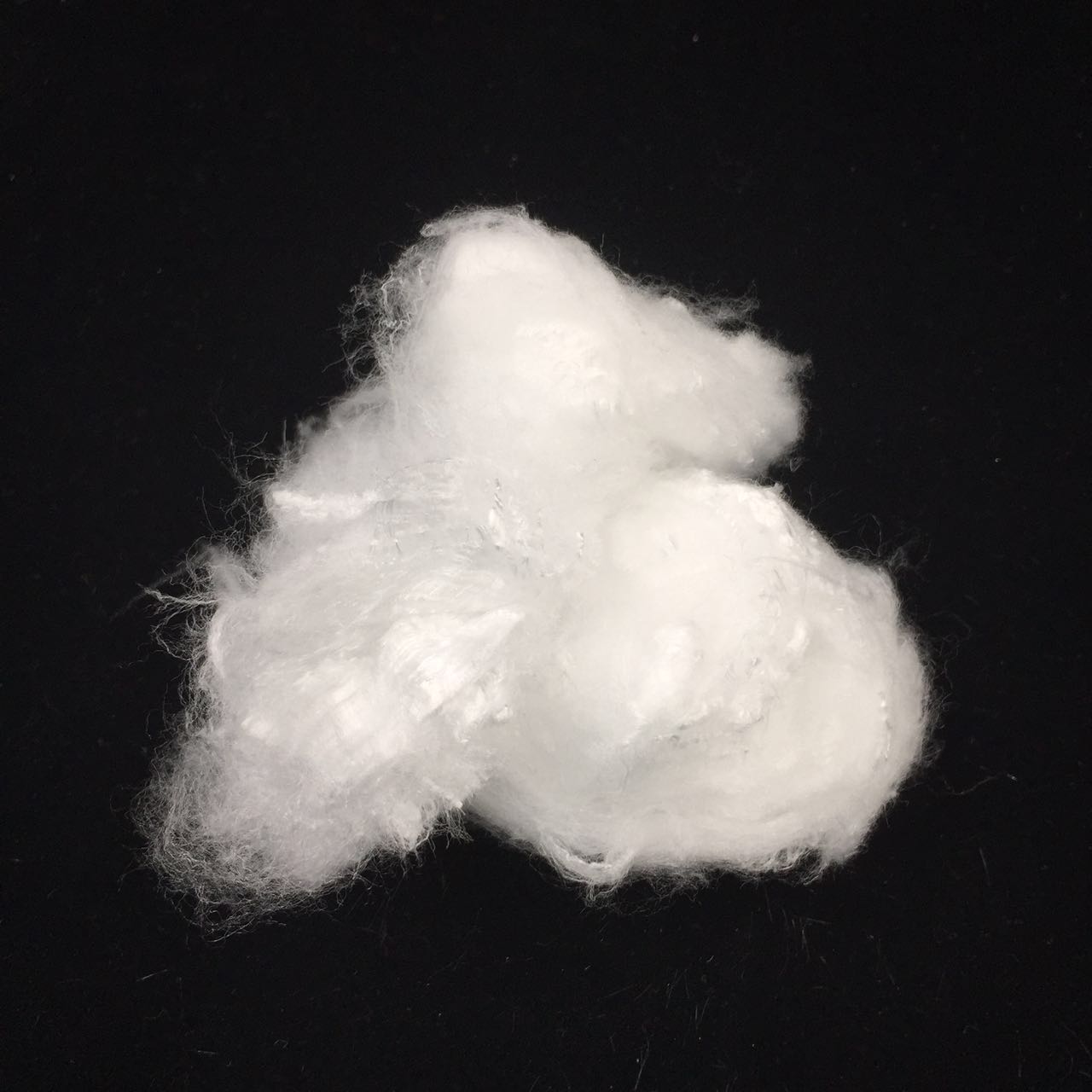

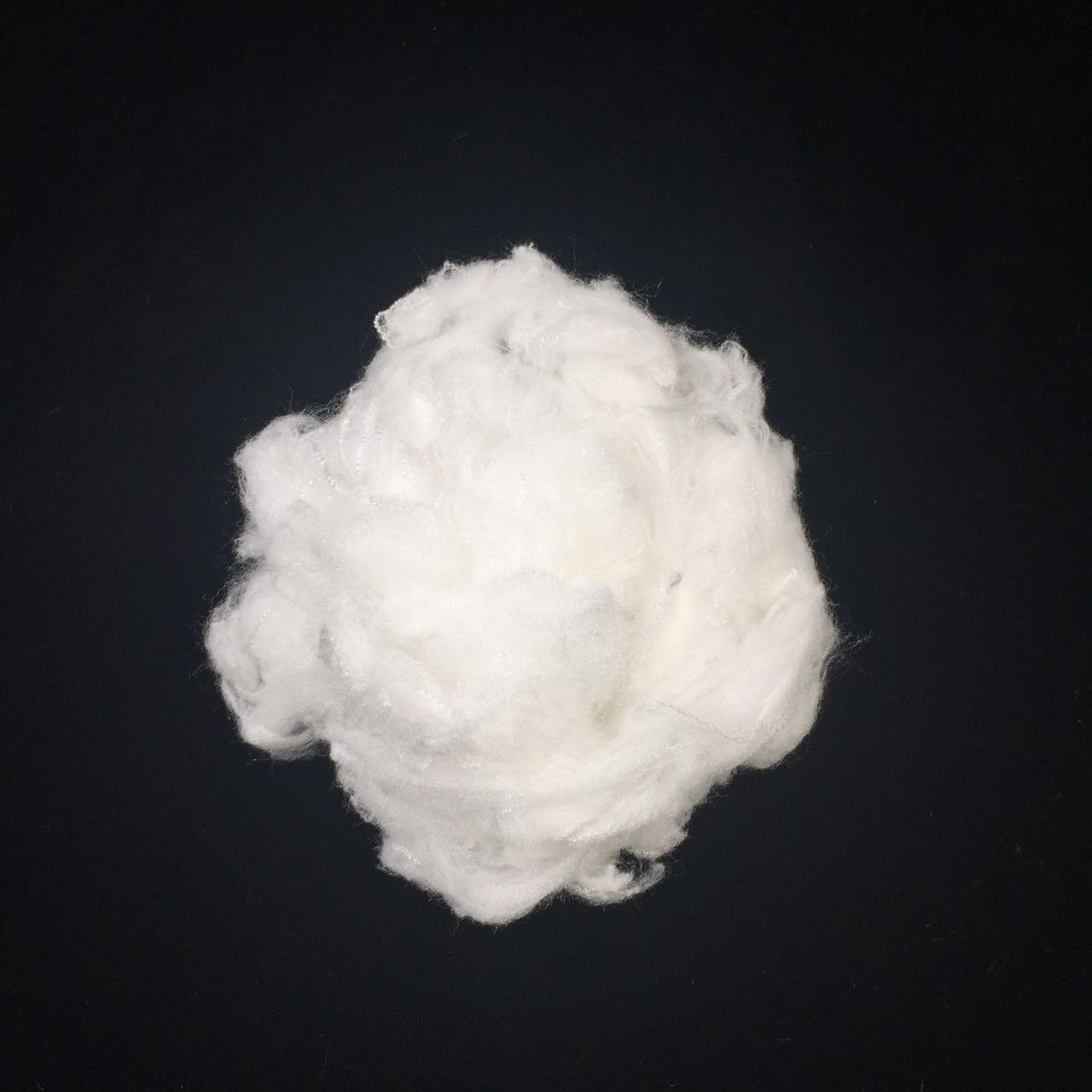

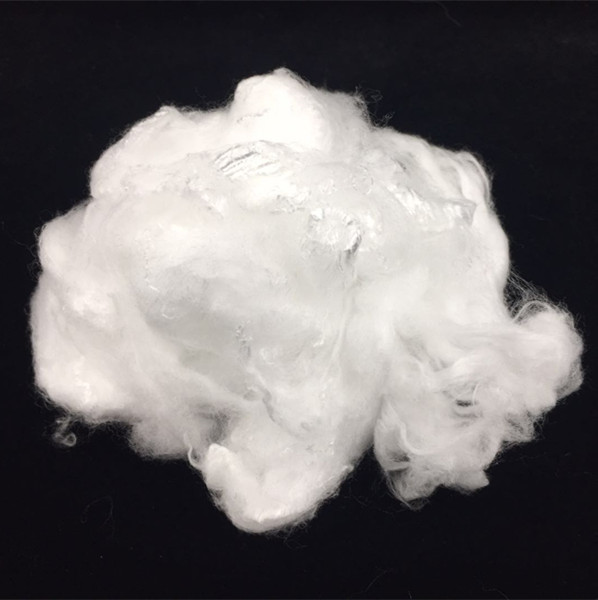

To appreciate the capabilities of this material, it's helpful to understand the basics of Nylon 66 production. The process begins with a chemical reaction called polymerization, where two molecules, hexamethylenediamine and adipic acid, are combined under precise conditions. This reaction forms long, repeating molecular chains, creating the raw polyamide 66 polymer, often produced as pristine white pellets. These pellets are the foundational building blocks. To create the final fiber, the polymer is melted, purified, and then extruded through a spinneret—a device with tiny holes—to form continuous filaments. These filaments are then stretched and cooled to align the polymer chains, significantly increasing their strength and tenacity. This meticulous process ensures that high-quality products like Invista nylon fibers possess uniform consistency and exceptional durability.

Exploring Polyamide 66 Properties

What makes this material so sought after are its outstanding polyamide 66 properties. Chief among them is its high tensile strength and excellent abrasion resistance, meaning it can withstand significant wear and tear without degrading. This toughness is complemented by remarkable elasticity and resilience, allowing the fiber to stretch and recover its original shape repeatedly. Furthermore, nylon 66 boasts a high melting point and good resistance to heat and various chemicals, which is critical for industrial and automotive applications. The inherent qualities of the PA66 material make it superior for applications where reliability is non-negotiable. Its ability to be engineered for high tenacity further expands its use, providing a lightweight yet incredibly strong solution for modern manufacturing challenges.

A Guide to Nylon 66 Applications

This guide to nylon 66 applications showcases its remarkable versatility across diverse sectors. In the textile industry, it is a key component in everything from resilient carpeting and upholstery to high-performance activewear and hosiery. Brands specializing in Invista textiles leverage the fiber's softness, durability, and dyeability to create fabrics that are both functional and comfortable. In the automotive world, its strength and heat resistance make it ideal for tire cords, engine covers, airbags, and various molded parts. Beyond that, its industrial uses are vast, including the manufacturing of ropes, parachutes, conveyor belts, and industrial brushes, where failure is not an option. These widespread applications underscore its status as a premier engineering material.

How to Select the Right PA66 Fiber

Choosing the correct PA66 fiber is crucial for ensuring the success of your final product. When sourcing this material, it is important to consider the reputation of the manufacturer and the consistency of their product. Premium-grade polymers, identifiable by their purity and uniform pellet size, lead to better performance and fewer defects during production. For applications requiring extreme durability, look for high-tenacity variants specifically engineered for superior strength. Evaluating the technical data sheet for the PA66 material can provide key insights into its specific tensile strength, elongation, and thermal properties. Ultimately, partnering with a trusted supplier who prioritizes quality control will empower you to create products that redefine longevity and performance.

In conclusion, nylon 66 fiber remains an indispensable material in modern engineering and design. From its complex production process to its exceptional properties and vast range of uses, it offers a solution that perfectly balances strength, flexibility, and reliability. As technology advances, the innovation potential for this incredible polymer will only continue to grow, solidifying its role as a fundamental component in creating the high-performance products of tomorrow.