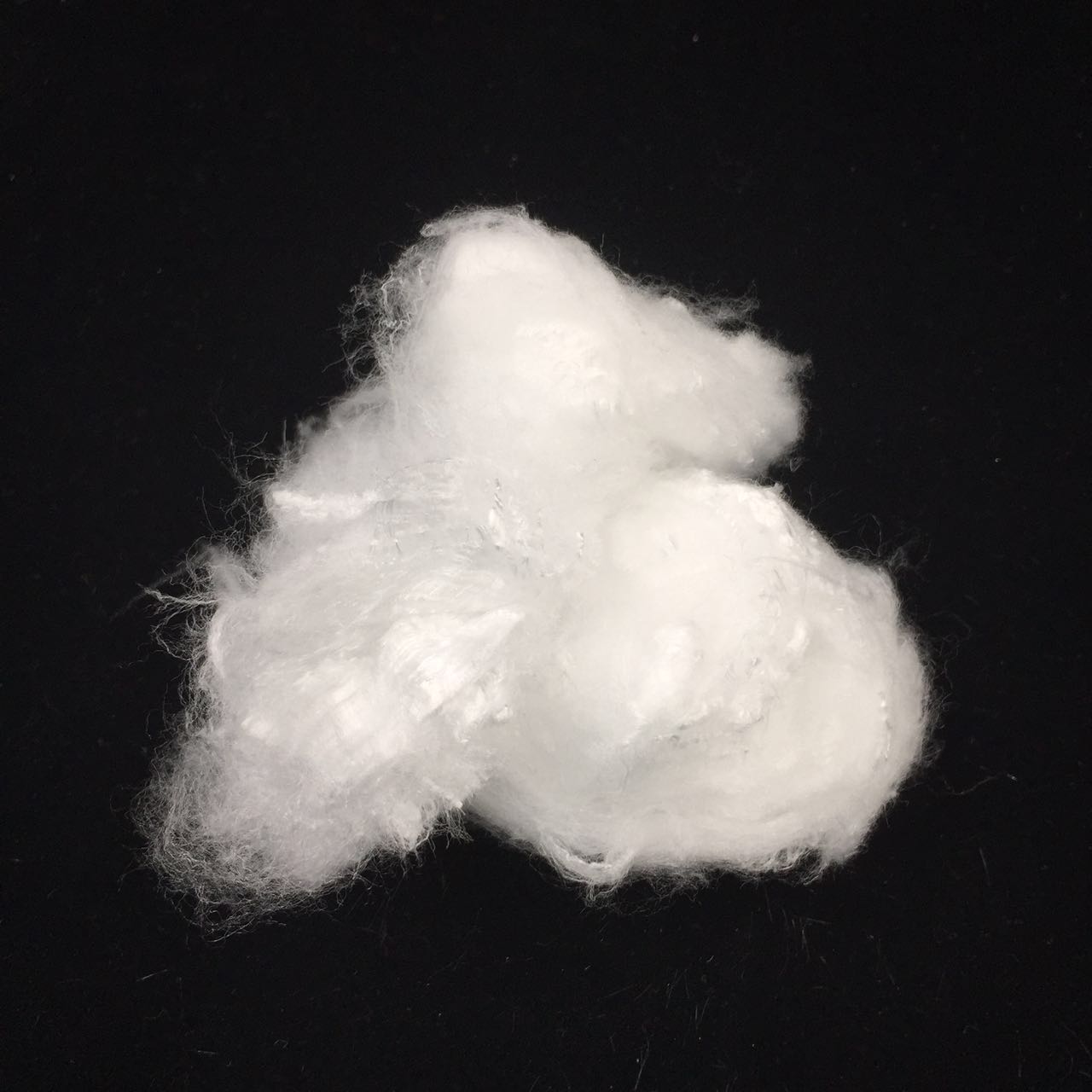

A Comprehensive Guide to Nylon 66 Fiber

When it comes to high-performance synthetic polymers, few materials can match the versatility and reliability of nylon 66 fiber. This remarkable material, also commonly referred to as PA66 fiber, serves as a cornerstone for countless industries, from automotive manufacturing to high-fashion textiles. Understanding its unique characteristics, production process, and applications is crucial for engineers, designers, and manufacturers looking to leverage its superior performance. In this guide, we will explore everything you need to know about this exceptional polymer, highlighting why innovators and industry leaders consistently turn to trusted sources like Invista for their material needs.

Understanding Polyamide 66 Properties

The widespread adoption of this fiber is directly linked to its outstanding polyamide 66 properties. As a PA66 material, it boasts an exceptional combination of high tensile strength, rigidity, and hardness, making it incredibly resistant to wear, abrasion, and repeated impact. Furthermore, it exhibits excellent thermal stability, maintaining its structural integrity at elevated temperatures, which is a critical feature for demanding automotive and industrial uses. Its resistance to a wide range of chemicals, oils, and greases adds another layer of durability. This unique blend of characteristics ensures that products made from nylon 66 are not only strong and tough but also have a long service life, providing reliable performance batch after batch.

The Science Behind Nylon 66 Production

The journey of creating this advanced material is a marvel of chemical engineering. The process of Nylon 66 production involves a specific type of polymerization known as step-growth or condensation polymerization. It begins with two core monomers: hexamethylenediamine and adipic acid, each containing six carbon atoms, which is where the '66' designation originates. When these two chemicals react under controlled heat and pressure, they link together to form long polymer chains, releasing water as a byproduct. This process is meticulously controlled by producers to ensure the resulting polymer has consistent molecular weight and structure. The molten polymer is then extruded through a spinneret to form continuous filaments, which are then stretched and wound into the final Invista nylon fibers, ready for their vast range of applications.

Exploring Diverse Nylon 66 Applications

The exceptional properties of this polymer translate into an incredibly broad spectrum of nylon 66 applications. In the automotive industry, its strength and heat resistance make it ideal for engine components, airbags, and tire reinforcements. For industrial settings, it's used to create durable ropes, nets, conveyor belts, and engineering plastics. The textile world also heavily relies on this material. High-performance Invista textiles, found in premium outdoor gear and athletic apparel, leverage its toughness and light weight for superior durability. Even in our homes, this versatile fiber is present in high-traffic carpets and resilient upholstery, demonstrating a reach that spans from heavy industry to everyday consumer products. The sheer number of uses highlights its status as a foundational PA66 material for modern innovation.

Choosing the Right High-Performance Fiber

With the technical details understood, the final step for any manufacturer is sourcing the material. When selecting a PA66 fiber, it is essential to partner with a supplier that guarantees quality, consistency, and innovation. Look for industry leaders known for their rigorous production standards and cutting-edge research. A premier supplier like Invista provides more than just a product; they offer scalable solutions, packaged for large-scale industrial efficiency, and backed by a global reputation for excellence. Whether you require durable fibers for demanding industrial tasks or refined Invista textiles for consumer goods, choosing a trusted source ensures that the final product benefits from the full potential of polyamide 66 properties. This commitment to quality is what transforms a simple raw material into the backbone of revolutionary products.