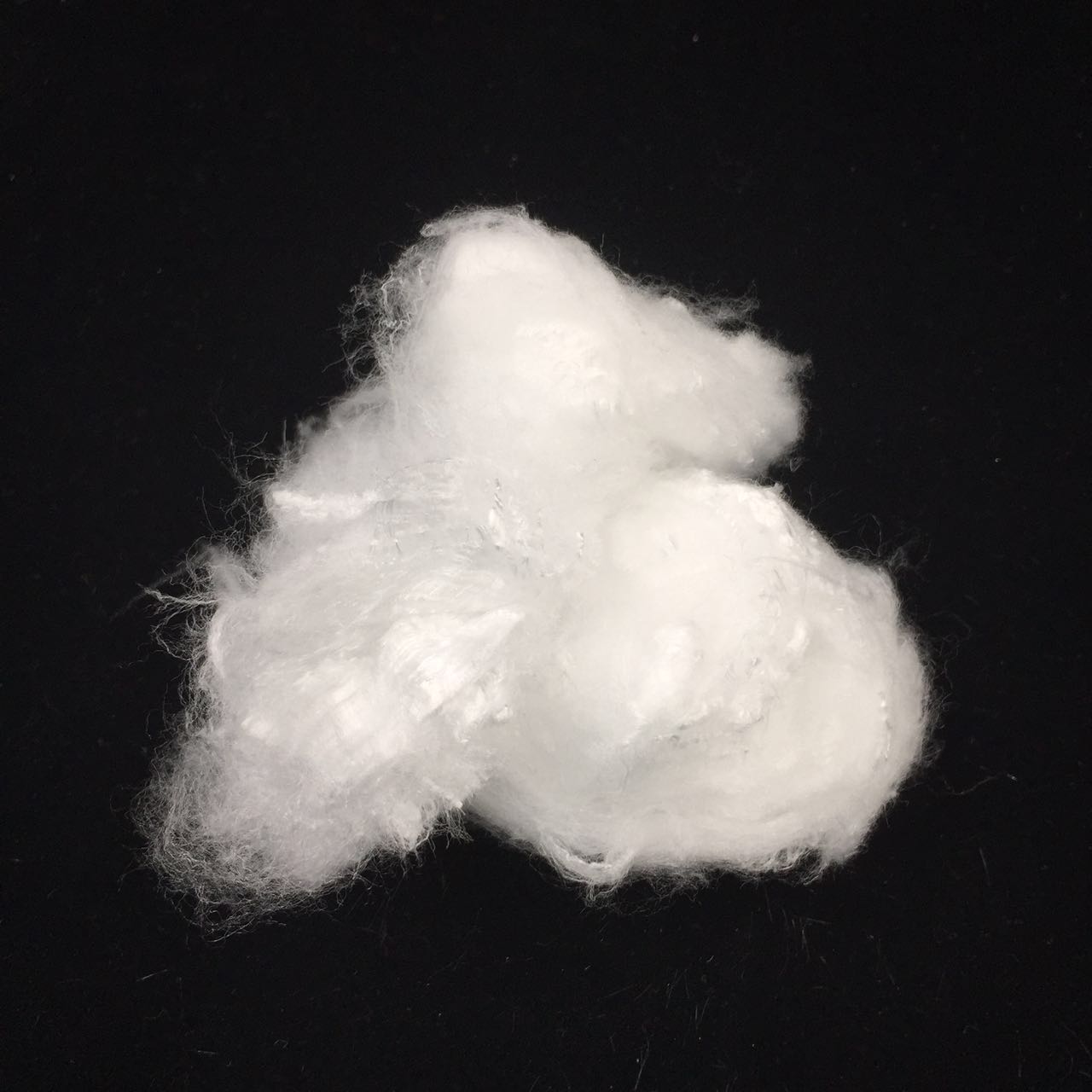

If you are searching for a high-performance material ideal for demanding industrial or textile uses, understanding nylon 66 fiber is essential. This versatile synthetic material, also known as PA66 fiber, is a cornerstone of modern manufacturing, celebrated for its exceptional strength, durability, and resistance to wear. This guide will walk you through the properties, production, and applications of this remarkable fiber, helping you understand how to leverage its benefits for your projects.

What Exactly is Nylon 66 Fiber?

At its core, nylon 66 is a type of polyamide created through a specific chemical process involving two monomers, each containing six carbon atoms, which gives it the '66' designation. This unique molecular structure is the source of its remarkable polyamide 66 properties, including high tensile strength, excellent elasticity, and a crystalline structure that contributes to its robustness. Unlike some other polymers, it maintains its integrity under significant mechanical stress and over a wide range of temperatures, making it a highly reliable choice for long-lasting products.

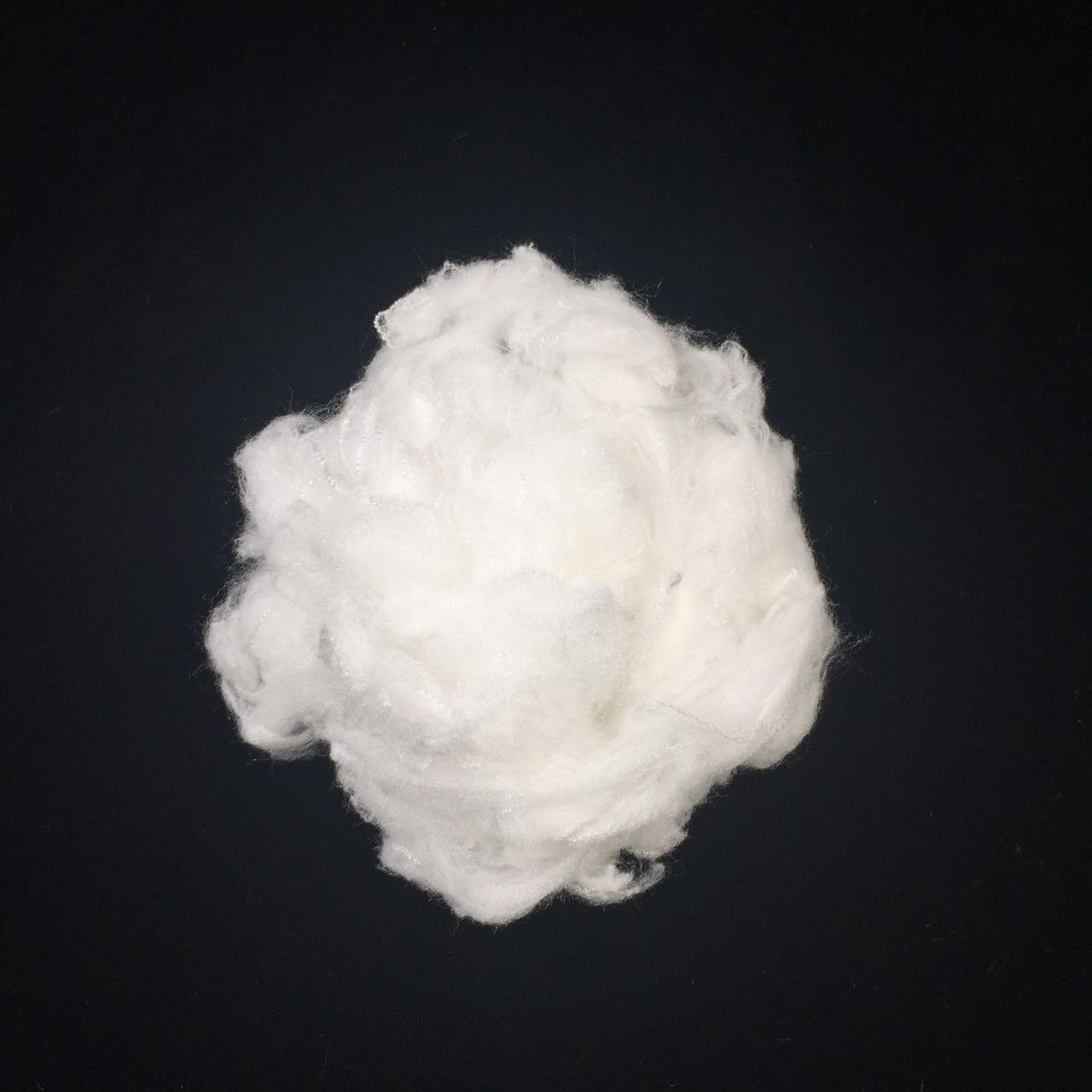

The Production Process: From Polymer to Fiber

The journey of creating this impressive material begins with Nylon 66 production. The process starts with high-quality polymer granules, which are melted down into a viscous liquid. This molten polymer is then extruded through a device called a spinneret, which contains many tiny holes, forming continuous filaments. As these filaments cool, they solidify and are stretched or 'drawn' to align their molecular chains, significantly increasing their strength and resilience. Companies that specialize in polymer engineering, such as those producing Invista nylon fibers, have perfected this process to create fibers with exceptional consistency and performance characteristics, turning a raw PA66 material into a high-tech fiber.

Key Properties of PA66 Material

The unique polyamide 66 properties are what make it a standout choice across countless industries. One of its most valued attributes is its high melting point, making it suitable for applications exposed to elevated temperatures, such as in automotive engine compartments. Furthermore, its excellent abrasion resistance means it can withstand constant friction without breaking down, a crucial feature for industrial components, carpeting, and performance apparel. The PA66 material also offers good resistance to a wide range of chemicals, oils, and solvents, which further expands its utility in challenging operational environments.

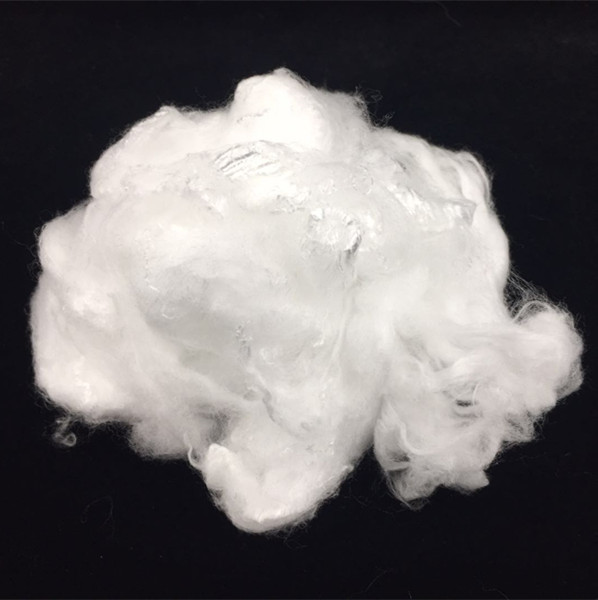

A World of Possibilities: Nylon 66 Applications

The superior characteristics of nylon 66 fiber translate into an extensive range of practical uses. In the textile industry, it is a key component in products that demand durability, such as robust carpets, high-performance athletic wear, and sturdy upholstery, often found in high-end Invista textiles. Its impressive strength-to-weight ratio makes it invaluable in the automotive sector for creating lightweight yet strong components like engine covers, airbags, and tire cords. The scope of nylon 66 applications also extends to industrial uses, including manufacturing conveyor belts, ropes, fishing lines, and precision-engineered plastic parts, showcasing its incredible versatility and reliability.